In the o ring industry another hardness scale is used due to the curved surface of the o ring cross section causing problems with accurately reading shore a.

O ring hardness measurement.

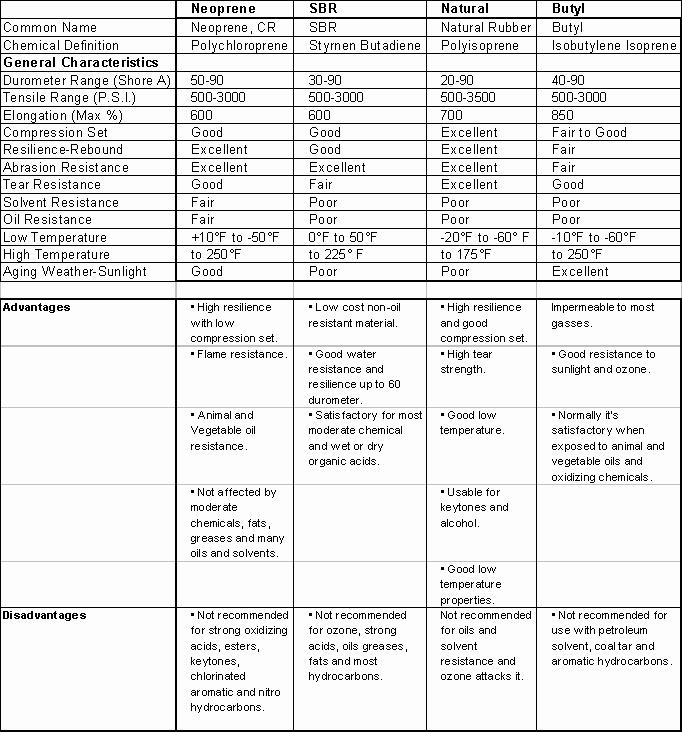

Durometer shore a scale is a type of measurement for rubber material hardness.

Shore a hardness testing is performed using a durometer which was developed by albert ferdinand shore in the 1920s.

Thus if you need a rubber or o ring durometer that feels like a running shoe sole review our rubber hardness chart below then pick shore 70a.

The hardness of rubber compounds is measured by the shore a durometer.

The size and shape of the indentor used in irhd readings is much smaller thus allowing for more accurate measurements on curved.

There is shore 00 shore a shore d and others as well.

This is particularly important in low pressure seals that are not activated by fluid pressure.

The hardness of rubber o ring compounds are measured by the shore a durometer.

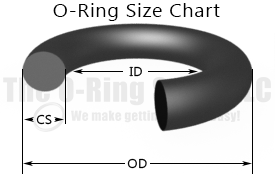

O ring sizes are specified by the inside diameter outside diameter od and the diameter of the cross section thickness.

Thus if you need a rubber or o ring durometer that feels like a running shoe sole review our rubber hardness chart below then pick shore 70a.

The shore a type durometer scale is generally used to measure the hardness of most rubber.

This silicone o ring has a shore durometer of 70a.

Generally most rubber materials fall under the rubber durometer scale of shore a.

The higher the durometer the harder the compound.

Technical handbook o rings o ring hardness the hardness of an o ring is important for several reasons.

The measurements are either in inches or in millimeters.

An o ring sizing cone how to measure o ring dimensions.

Shore durometer is the hardness of a material and its resistance to permanent indentation.

The shore a hardness measurement is often colloquially called durometer or duro.

Durometer is the international standard for measuring the hardness of objects like rubber and plastic.

This test is performed on cured rubber sheets per astm d2240 and on finished o rings per astm d1414.

There are a few different measurement scales call shores.

A rubber durometer of shore 70a is the most commonly chosen material hardness for all applications.

The higher the durometer the harder the compound.

The softer the elastomer the better the seal material conforms to the surfaces to be sealed and lower pressure is required to create a seal.

70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o rings applications.

The scale is irhd international rubber hardness degrees.

In the uk o ring sizes are specified by the british standard bs and each ring size has a related bs number.

70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o ring applications.